For Immediate Release, August 1, 2025

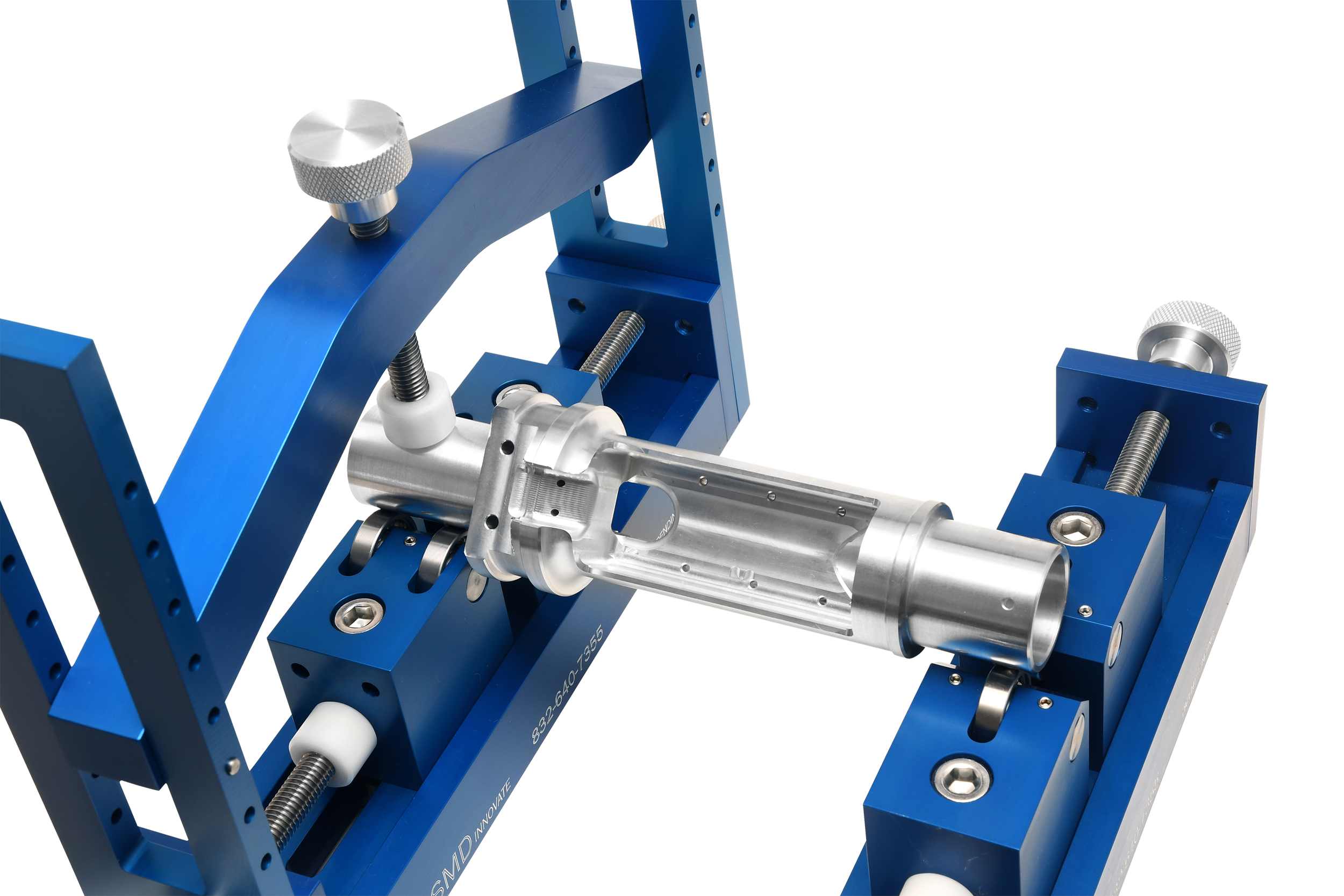

SMD Innovate Unveils Industry-First AVB Adjustable Roller V-Block Kit

Precision Meets Protection in this new Inspection and Setup Tool for Cylindrical and Short Part work holding

Steady Rest for 4TH Axis Milling applications and Rotary milling operations

Houston, TX – Smith Machine Dynamics (SMD Innovate), Houston’s trusted name in precision machining, proudly announces the release of its latest innovation: the AVB Adjustable Roller V- Block kit This groundbreaking tool redefines how machinists, inspectors, and quality control professionals handle cylindrical and short part orientation, leveling, and runout inspection — without compromising surface finishes.

Purpose-built for CMM environments and precision inspection rooms, the AVB Adjustable Roller V Block Kit introduces an industry-first double locking bearing system that enables precise positioning and secure locking of diametrical and horizontal workpieces. The Delrin-tipped top clamp ensures that delicate, finely finished parts are held securely without damage — eliminating costly rework caused by scratches during final inspection.

“This is more than an inspection device- it’s a productivity upgrade for anyone working with tight-tolerance components,” said a spokesperson for Smith Machine Dynamics. “Our customers asked for better control, easier adjustment, and no compromise on finish quality. The AVB delivers on all fronts.”

Key Features:

Adjustable Stainless Steel Ball Bearings: Smooth rolling, adjustable to hold diameters from 0.125" up to over 16".

Double Bearing Slide Mechanism: Allows for accurate part orientation — even on short pieces — with secure locking in both radial and axial directions.

Delrin-Tipped Top Clamp: Prevents scratching or marking precision-machined surfaces while securing workpiece in place in combination with our locking bearing feature

Knurled Adjustment Knobs Fine-tune the level and position of parts with minimal effort.

CMM-Friendly Design: Ideal for automated and programmable metrology systems

Designed for maximum versatility and protection, the AVB Kit provides machinists and inspectors with a dependable solution for concentricity checks, straightness verification, total indicator runout (T.I.R.) measurement and Mill Steady Rest for rotary work holding in 4th axis operations

This product is an extension of SMD Innovate’s commitment to delivering advanced solutions tailored for Houston’s demanding energy, petrochemical, and industrial sectors. Since 2017, Smith Machine Dynamics has earned a reputation for quality, precision, and innovation — serving the Gulf Coast with ISO-level quality control and CNC machining capabilities that deliver tolerances down to ±0.0005".

The AVB Adjustable Roller V Block Kit is now available directly through SMD Innovate’s Houston facility. For more information, quotes, or ordering, visit www.smithmachinedynamics.com or call (832-6407355)

About Smith Machine Dynamics:

Located in Northwest Houston, Smith Machine Dynamics is a precision machining and manufacturing facility serving the Gulf Coast’s industrial backbone. Specializing in CNC machining, component prototyping, and inspection tooling, SMD delivers quality and reliability to energy, petrochemical, and industrial sectors.